Smarter Grinding: Faster, Preciser, Stabler!

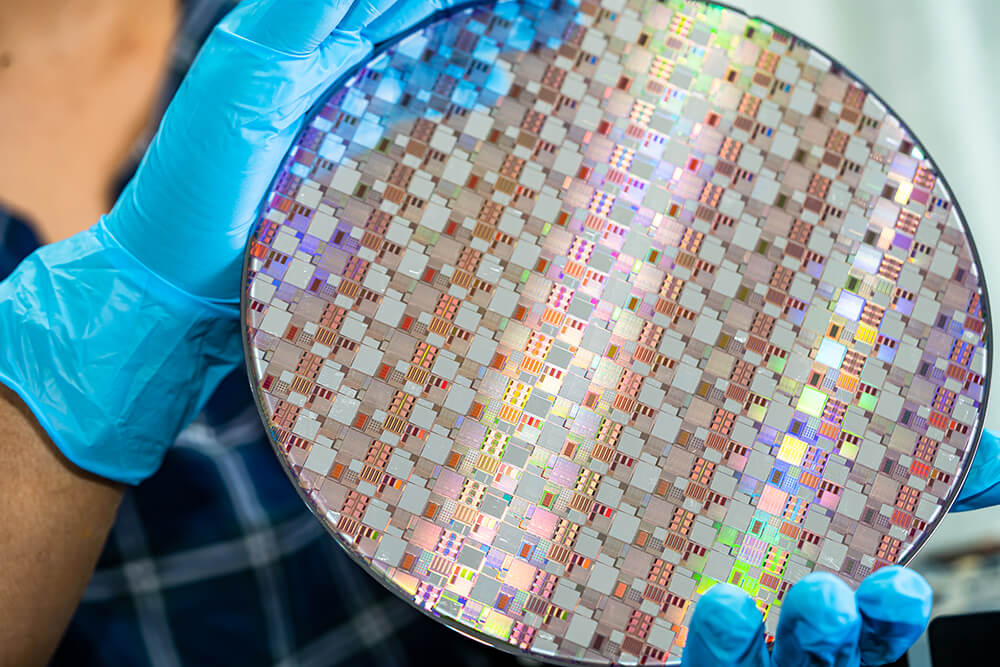

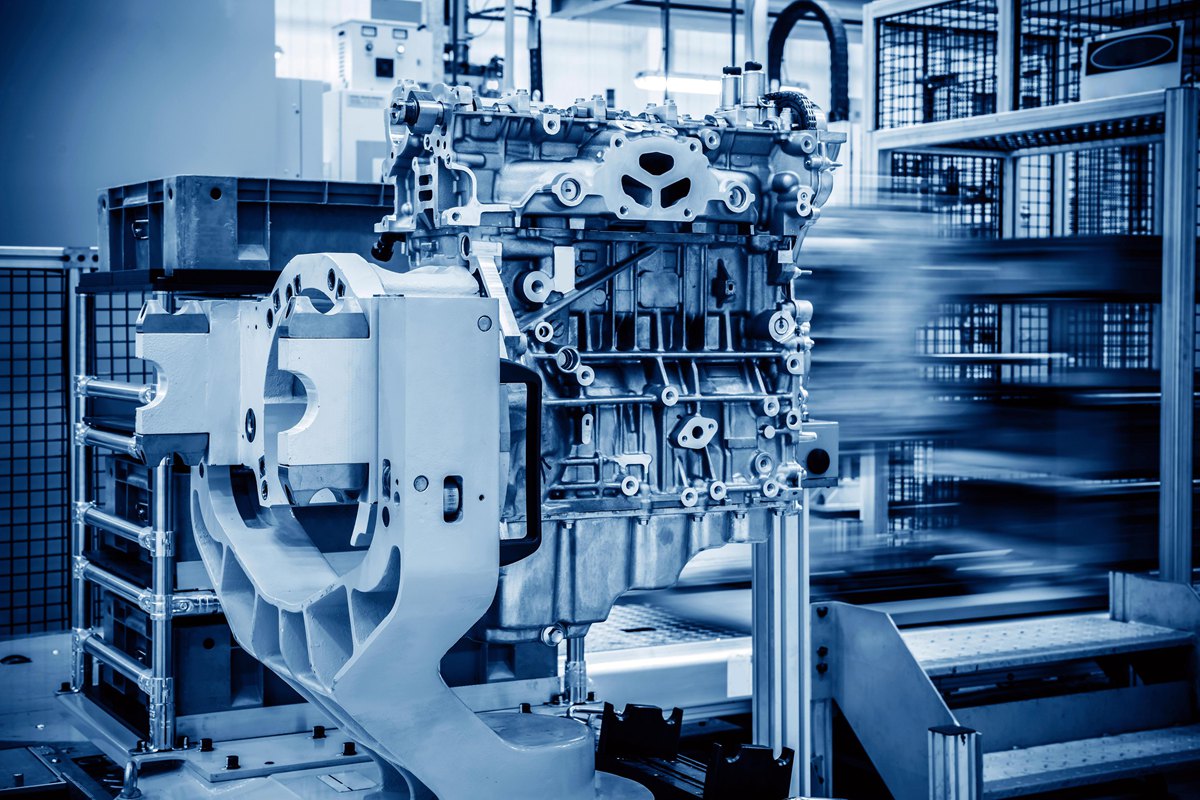

HK Xinyutong Optoelectronics Co., Ltd.. was established in 2009 and is located in Songgang Dingfeng High-tech Industrial Park, Bao'an District, Shenzhen. The company focuses on the R & D, production and sales of high-

end grinding and polishing products. Its product line covers various grinding and polishing materials such as diamond, alumina, silicon carbide, cerium oxide and silicon dioxide. At the same time, it provides a full range of products including grinding fluid, grinding

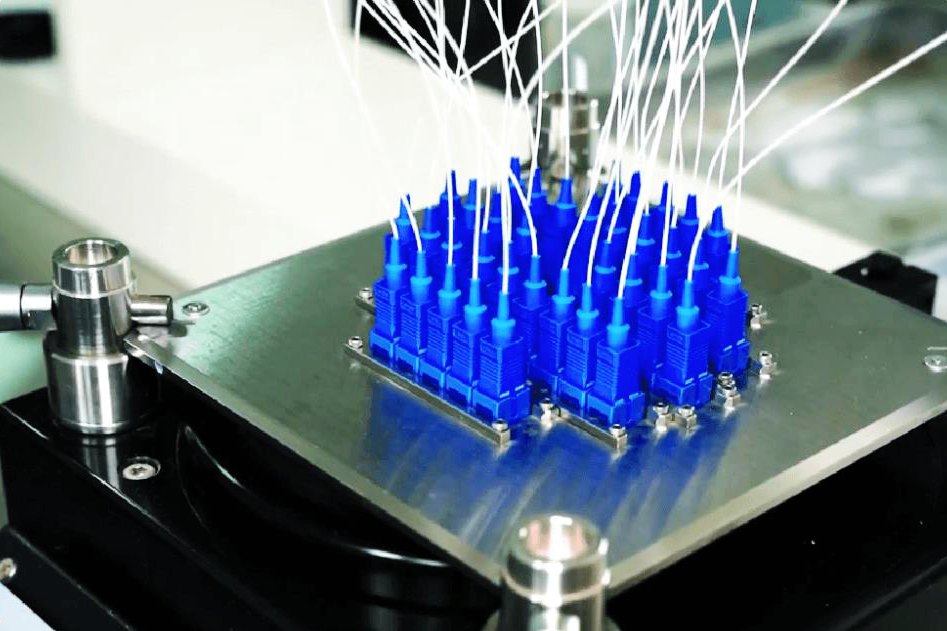

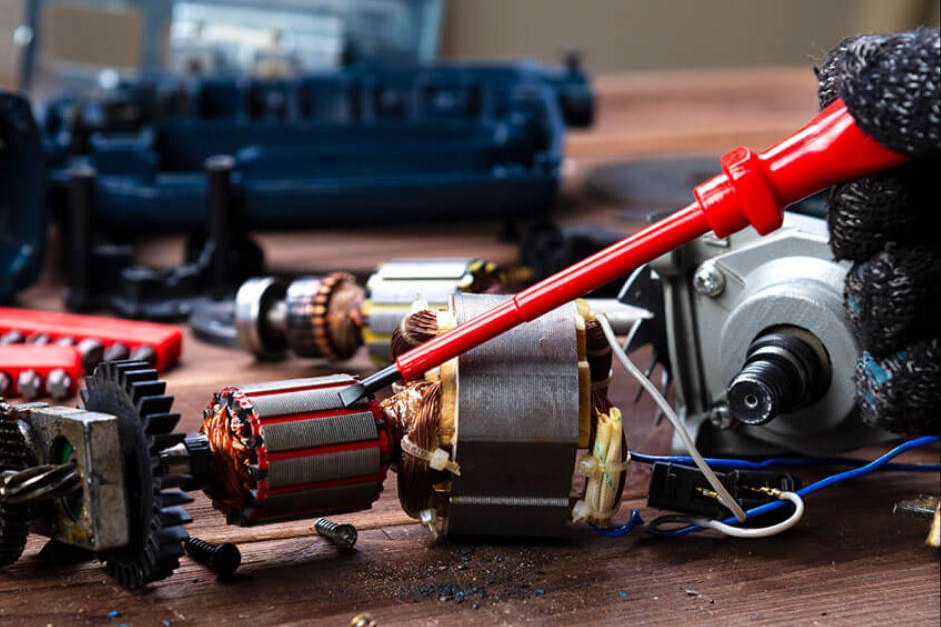

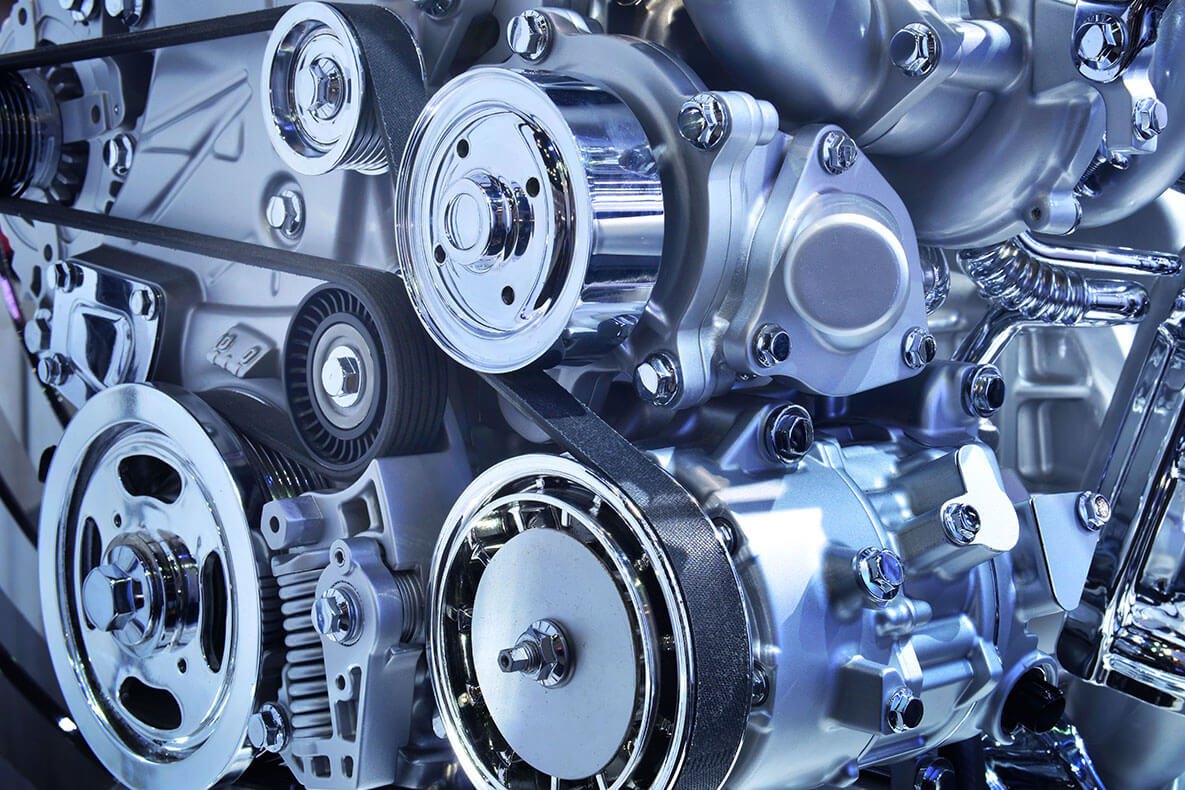

oil, grinding pad, polishing equipment, etc., and is committed to providing one-stop grinding and polishing solutions for industries such as optical fiber communication, optics, automotive, aviation, digital, electronics, metal, crankshaft, roller making and micro-

motor.

The company's park covers an area of 125 mu, and the factory building area is 12,000 square meters. We have introduced large-scale high-end precision coating production lines at the domestic leading and international first-class level, and supporting

construction of an optical-grade quasi-thousand-level dust-free purification workshop, a first-class R & D center, a high-standard slitting center, a warehousing center, as well as advanced hardware facilities such as efficient RTO waste gas treatment

equipment.

Relying on unique production processes, patented formulas, full-automatic control, online automatic detection, strict quality monitoring and other advantages, Xinyutong has filled the gap of Chinese manufacturing and Chinese brands in the high-end grinding and polishing market, and is committed to leading Chinese manufacturing and Chinese brands onto the global stage.

-

25+

Years experience

-

85+

country/region

-

3000+

Applications

-

12000+

Factory area

English

English 中文

中文